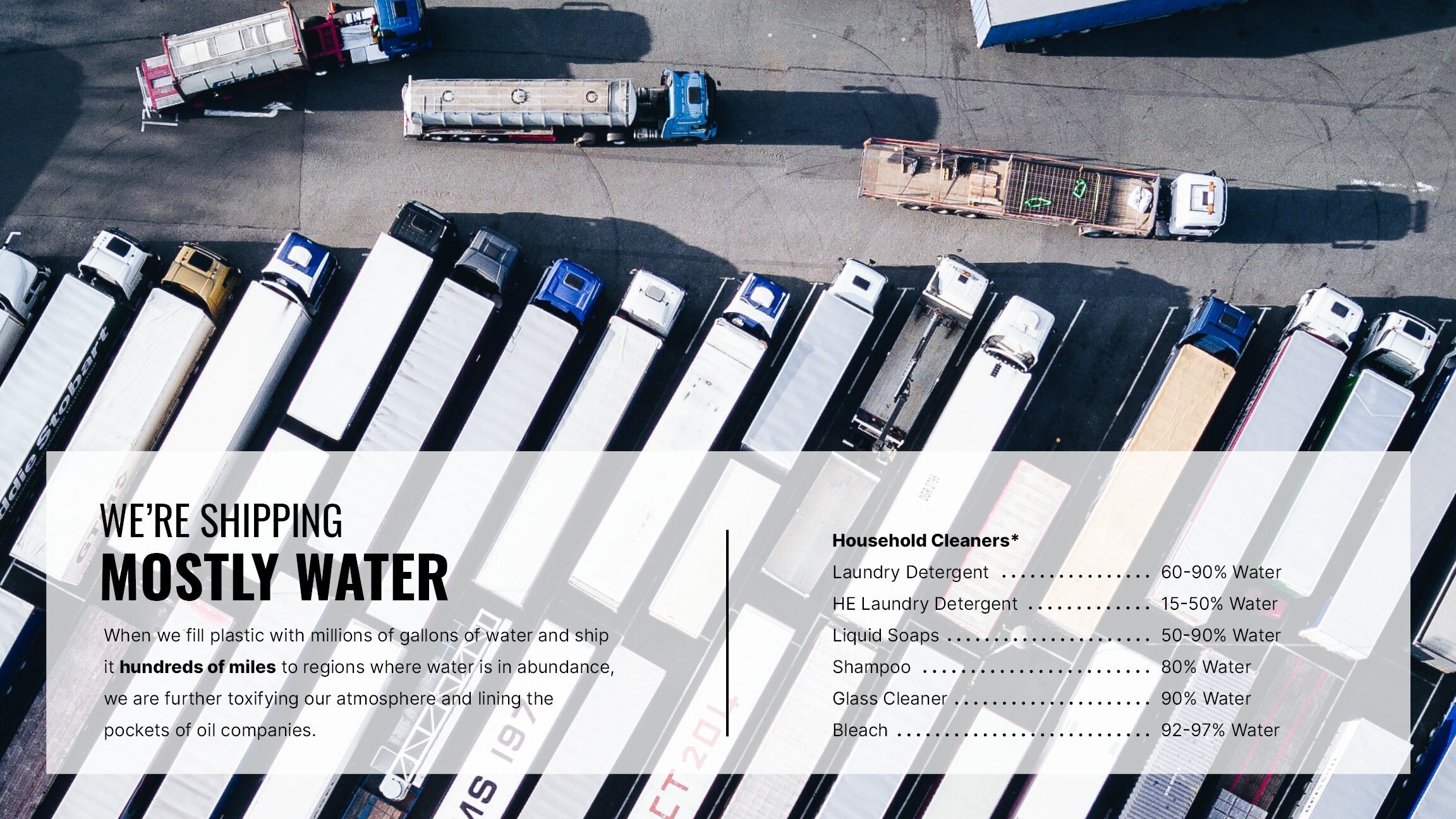

Nearly 40% of plastic is used only once, leading to decades of accumulation in landfills and the natural environment. Less visible but equally damaging are the emissions from refining crude oil into plastic, methane released from its decomposition, and fuel burned moving it around the world. When we fill that plastic with millions of gallons of water and ship it to regions where water is in abundance, we are further toxifying our atmosphere and lining the pockets of oil companies.

This concept looks at how we can challenge our consumption behavior around the hidden inefficiencies of household cleaners. System architecture, user experience design, and careful material substitutions are used to remove virgin plastic from the equation and add water at point of use. My work explores how design and responsible service models can lead us toward low-impact consumption and better stewardship of our environment and natural resources.

Introduction

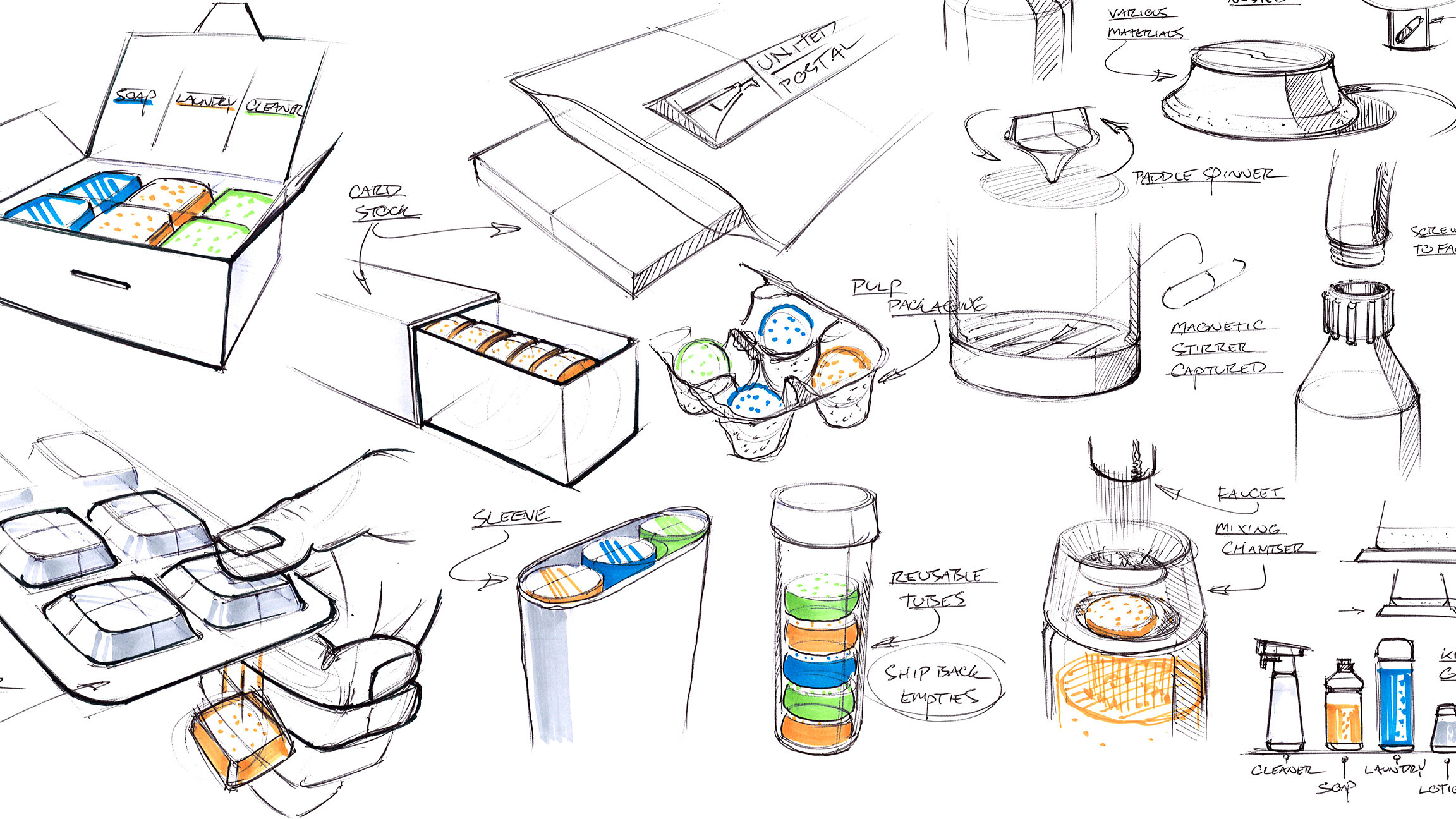

Process

To lower the need for all of this plastic, I wanted to explore a system that would allow you to make your own cleaners. That required doing a deep dive into the chemistry and inherent economics of these liquids. I was able to learn a great deal from various DIY communities online, that knocked off everything from laundry detergent to antibacterial cleaner, using an array of blenders, graters, buckets, long recipes and obscure bulk ingredients.

I needed a method for incorporating this science-y know-how and labor intensive tasks into a form factor that was as convenient as the mass-market alternatives. This meant streamlining the workflow to limit opportunities for user error and dissatisfaction; i.e. tasks such as measuring, pouring, mixing, and dispensing.

I mocked up a prototype that used an old computer fan to spin a magnetic mixer in the same fashion as a common piece of laboratory equipment. This showed some promise as a suds-free method for blending solutions, while being quiet and low profile. Packaging and shipping solid concentrates also provided many environmental advantages over their liquid counterparts.

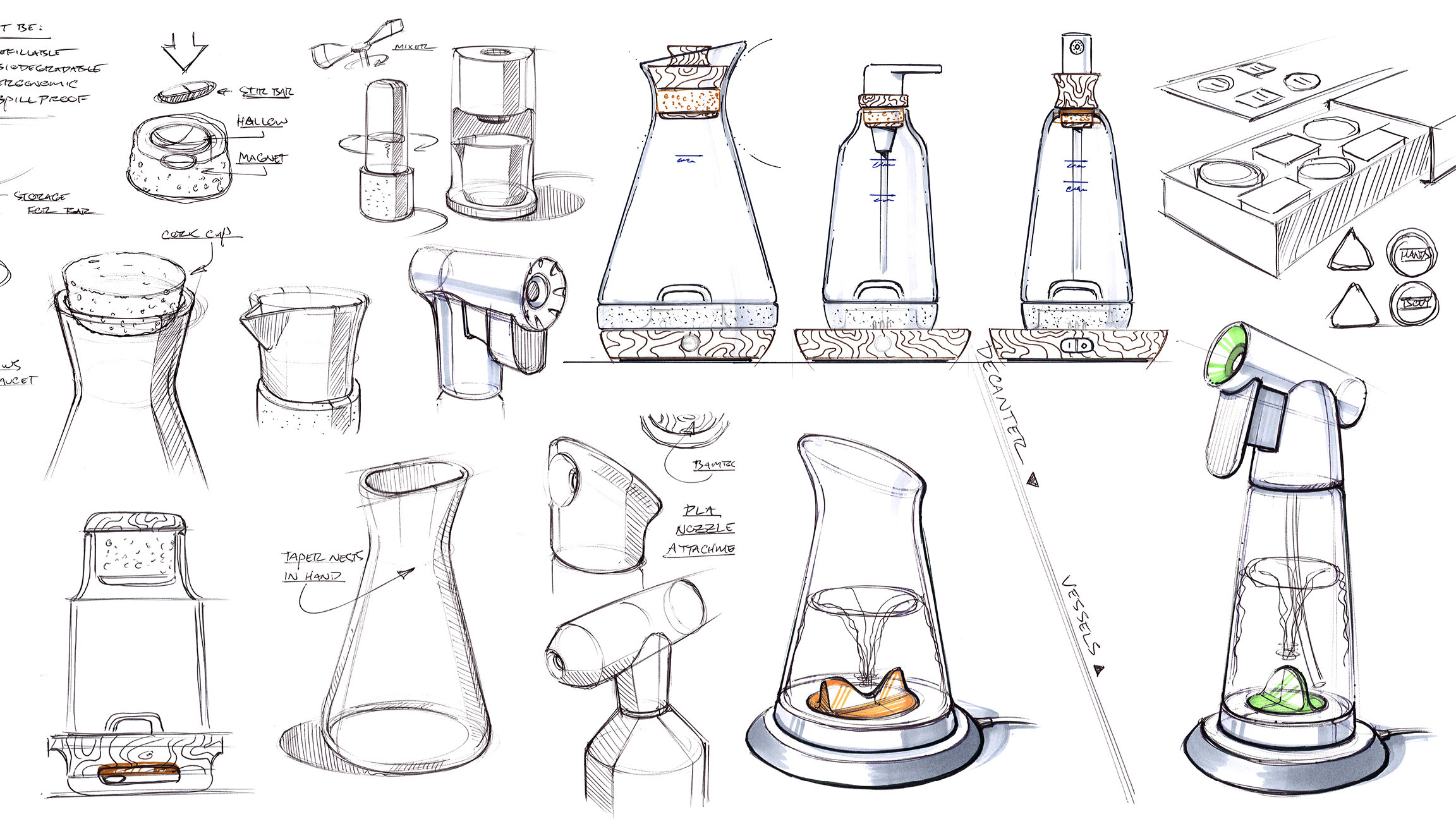

final design

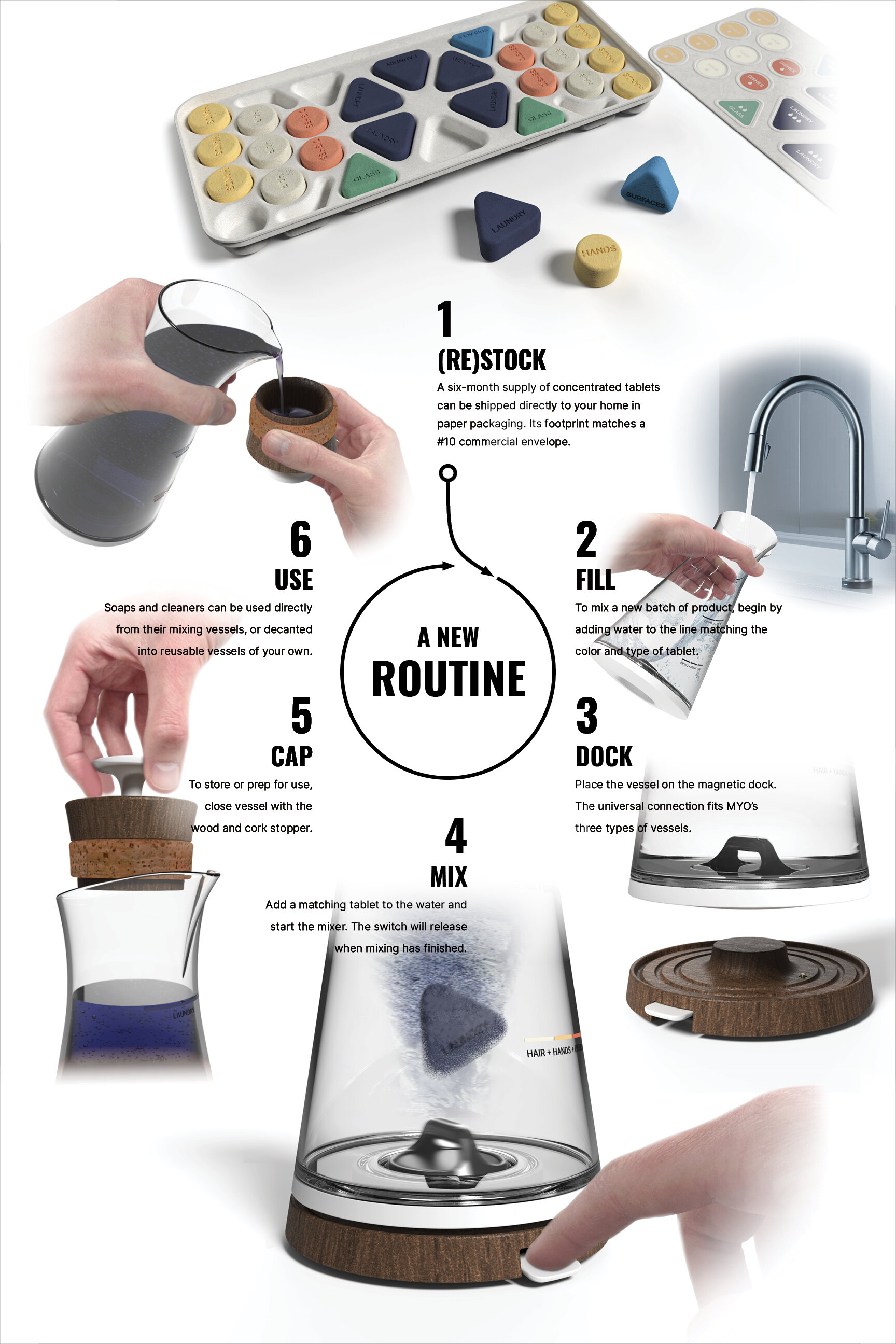

My proposed solution is an inexpensive system of reusable mixing vessels and concentrated tablets. Adding water at point of use reduces emissions from shipping by more than 95% and eliminates unnecessary single-use plastics.

Customers receive an envelope-sized package in the mail that contains tablets for a few months of cleaning, while the vessels can be either shipped or picked up at local stores. Each vessel is specialized for a cleaning function (pour, spray, pump) and has labeled fill-lines to make refilling measure-free. A customer could also use their own containers, using only the flask vessel and dock for mixing and decanting.

A cardstock liner informs the user of their water and carbon stewardship with each refill, reinforcing their nudge towards good behavior. Natural castile soaps and vegetable dyes compose the tablets, with circles / warm colors denoting those for the body, and triangles / cool colors for cleaners. The cleaner tablets are sized too large to fit into the pump vessel, intended only for solutions that are used on the body.

MYO’s form language draws inspiration from laboratory equipment and the Victorian apothecary. The tapered forms and curvature through the necks enhance grip, while the stoppers lend warmth, richness, and texture. The vessels could be molded from recycled PET, lending durability, a clear façade, and more freedom in its geometry. These would be lighter, safer, and more economically viable to recycle than glass (Indiana, USA, 2020). The stoppers and dock could be made from carved FSC certified domestic hardwoods (oak, walnut), paired with cork gaskets and white compostable bioplastics for the internal components. A magnet could be insert-molded in the spinner, which is safely captured in the threaded two-part vessel design.

Lastly, a label on the bottom of the dock offers instructions for returning the mechanism for service/decommission and recycling the vessels.

Takeaways

This project taught me a few lessons about sustainable product design that I’ll carry into future work.

Most importantly, renewable materials are most appealing when selected for their physical properties (not just aesthetics). Incorporating them will help their economic viability and condition customers to accept them.

Also, the end-of-life of your product must be designed, to guide your customers through the confusing waste stream landscape and towards models of environmentally-beneficial consumption.